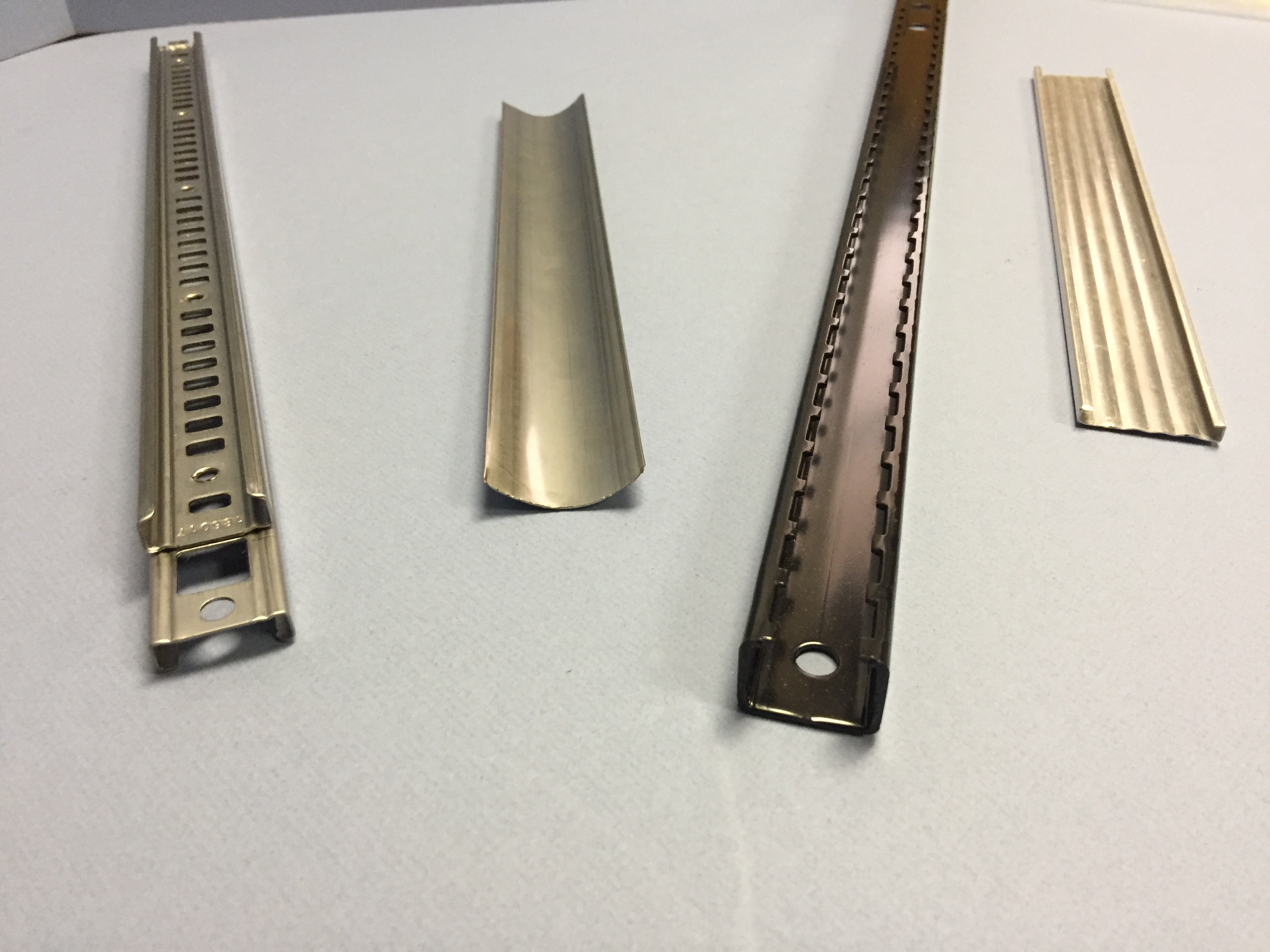

While the many of our customers like to take advantages of Roller Die + Forming’s Standard Tooling Library to help significantly cut the up-front cost of tooling, other customers have very specific and unique shapes they need. In these cases, custom metal forming is the best option for their parts as they can specify the exact shape, metal thickness, and length of their part. They can even punch holes in various patterns along the part, meaning their investment in tooling allows them to create a variety of parts.

For example, while we have a number of hat sections in our Standard Tooling Library, sometimes you just want your hat to look a little different. Maybe the sides are at an angle or the edges are rolled back in on themselves, or perhaps you want your shape to have a collection of different angles. Roller Die’s in-house team of engineers can work with you to design custom tooling that fits your needs. Then, our in-house tool room takes over to create your custom tooling and ensure your parts are produced exactly to your quality specifications.

Want a part with multiple bumps or ridges along the top or grooves on the side designed for sliding and locking to other parts? Our team can help determine whether roll forming is right for your part, but it’s amazing how complex some of the parts we roll can be. Whether out of steel, stainless steel, aluminum, or other metals, from appliance applications, drawer slides, automotive parts, tracks for AS/RS vehicles, and more. Reach out to our sales team today to learn how we can help you streamline your process, implement best practices in your designs, and meet quality standards.