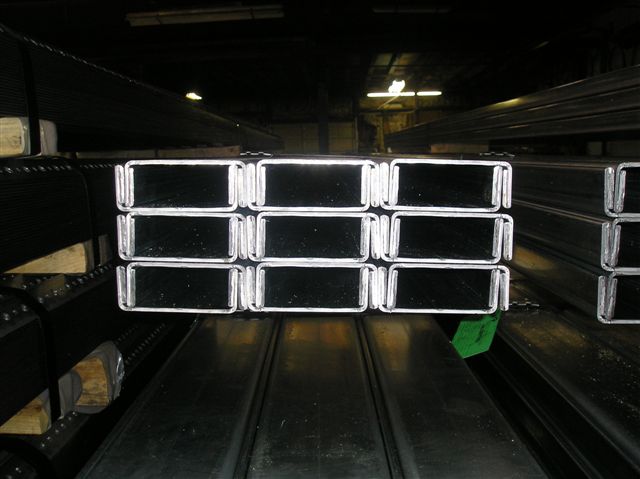

Roller Die creates parts for many industries, from solar to material handling, from conveyors to trucks. Many of our clients take advantage of manufacturing practices such as just-in-time delivery, having only the parts they need for the week or even the day show up at their plant while we adjust our output based on their demand. Other clients have us put together kits of multiple roll formed parts and deliver those kits to a job site. In each of these situations, different packaging is required to transport the parts from our facilities to the customer locations.

Especially when our customers are doing just-in-time delivery, but anytime we anticipate repeat orders, Roller Die works to make re-usable packaging, generally wood pallets or containers. We also work to cut down on the plastic waste in the packaging process. This is not only environmentally sustainable, it saves money for customers. Plastic wrap can trap moisture next to metal parts while storing parts under a cover can prevent moisture problems on certain types of metal.

While wood packaging is reusable, it occasionally has to be repaired and replaced, just like custom tooling. Our team has shipped enough custom metal parts to be able to include those wear and tear costs in your packaging quote. (Custom tooling lasts significantly longer, but our team will certainly let you know how many years you can expect your tooling investment to last.) That’s the advantage of working with an experienced company.

If you’re interested in a custom metal roll formed part, reach out to a member of our sales team today. They can discuss your requirements, get you a quick quote from the Roller Die engineering team, and then guide you though our ordering process. From customer service to shipping, quality control to tooling, our team is always looking out for our customers and making sure we’re taking the necessary steps to manage costs and create reusable and sustainable solutions whenever possible.