With the new tariffs on steel and aluminum, many companies are taking a deep dive analysis of their supply chains to see where they can cut costs, improve quality, or get better service. Everyone is concerned that the price of raw materials and parts is on the rise and keeping prices in control for customers is important. Sourcing roll formed materials is no different and there are many things to consider while looking at different suppliers.

Cutting costs is often the first area procurement focuses on when reviewing suppliers. This can be done by buying raw material in bulk in order to secure a better price or by making a bulk parts purchase even if those parts will be delivered over the course of a year. Look to have your parts produced in areas where the labor costs are lower, such as Mexico. Finally, transportation of materials and parts between facilities can get expensive, so look at the location of the facilities in the different parts of your supply chain to see if moving to a closer supplier can help lower expenses.

Improving quality of materials and parts coming into your manufacturing process can help eliminate waste. Meet with your suppliers to learn about their quality control processes and how they work to eliminate waste.

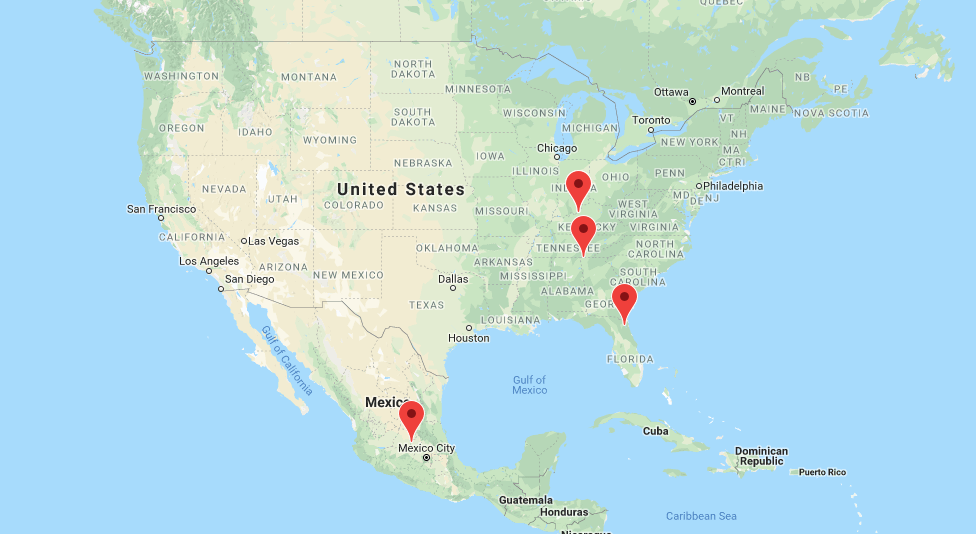

Combining good prices, logistics, and quality is important. When it comes with customer service, responsive and knowledgeable sales and engineering staff, and a willingness to help find creative solutions, then you’re probably working with Roller Die + Forming. Our locations throughout the southeast U.S. and Mexico are located within an easy distance of many major manufacturing centers. Our team takes pride in providing timely service with a strong understanding at all levels of roll forming.

If you’d like to learn more about Roller Die + Forming, our experienced sales team would be happy to tell you about our Standard Tooling Library. This is a great way for customers to cut up front costs. Look through the catalog or reach out today.