The team at Roller Die + Forming continues to closely monitor the price of steel, but that isn’t the only factor driving our prices. You’ve probably noticed from your own grocery shopping that what’s out of stock varies from week to week. At first it was toilet paper. Then other products, seemingly at random, would not be available. This was driven not only by the supply of raw materials but also by labor shortages, logistics issues, and even weather problems.

These unexpected shortages are driving significant hoarding behavior. While we may laugh at pictures of shopping carts stuffed with more toilet paper than a family can use in a year or incredibly unsafe images of the ways people are hoarding fuel, the same behavior patterns can impact businesses too. Of course, it doesn’t take much hoarding on a business-scale to create an impact in the economy.

These unexpected shortages are driving significant hoarding behavior. While we may laugh at pictures of shopping carts stuffed with more toilet paper than a family can use in a year or incredibly unsafe images of the ways people are hoarding fuel, the same behavior patterns can impact businesses too. Of course, it doesn’t take much hoarding on a business-scale to create an impact in the economy.

Bulk purchasing does have it’s advantages. We often encourage customers to project how much raw material they will use over the year so that we can take advantage of volume discounts when purchasing and plan our processes to ensure they are receiving the parts they need just in time. We are better able to plan materials, labor, and delivery and our customers are able to enjoy better prices.

However, when you bulk purchase without just in time delivery, you likely find yourself facing storage issues. Warehouse costs for parts you don’t currently need or haven’t yet sold can quickly eat into profit margins. Over purchasing commodities like raw materials can drive inflation, driving more businesses to purchase now while the prices are still low instead of later, which drives yet more price increases. These increases are passed all the way to the consumer, of course, who then demands higher wages in order to keep up with rising costs.

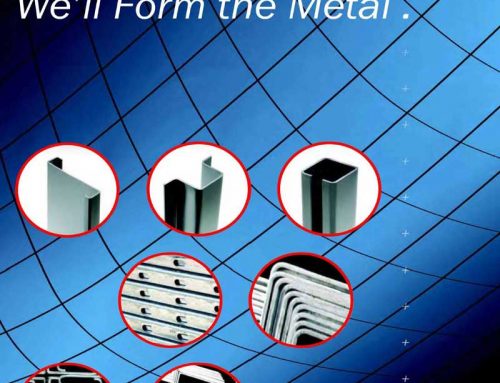

If you’re interested in roll forming, reach out to a member of the Roller Die + Forming sales team today. We can discuss your project and needs and help you understand how to purchase with the current steel and other metal prices.