Why Roll Formed Steel for the construction industry?

When you are running a construction company, setbacks and material prices are two of the biggest factors you have to consider when planning and budgeting for a project. When it comes to finding the right Steel for the Construction Industry, you want to find a provider for your parts that will be both cost effective, provide good service, and will deliver the parts in a timely fashion to prevent project delays.

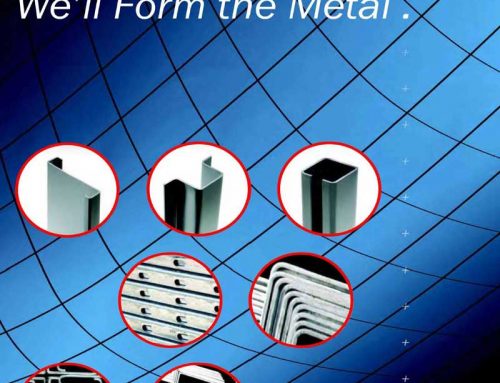

At Roller Die + Forming, we work to keep costs low and the process of roll forming flowing forward in a timely fashion. Roll forming uses engineered precision to ensure the metals become bent and shaped to the measurements given.

How does it affect the Construction Industry?

Construction businesses have to be both timely and cost-effective to create a practical timeline for their clients. They expect the same considerations from supplier and contractors, which they purchase roll formed steel for their construction projects from Roller Die.

Construction businesses have to be both timely and cost-effective to create a practical timeline for their clients. They expect the same considerations from supplier and contractors, which they purchase roll formed steel for their construction projects from Roller Die.

Fast – Once we have the technical drawings approved and the tooling set up, creating your part is as simple as taking the raw metal and running it through our rolling machine, punches, and dies on the line, making the process as fast as possible.

Cost-Effective – Because roll forming creates little waste, more of the raw material you purchase goes into the final product, making our process a cost-effective solution for producing large volumes.

Consistent – Thanks to the nature of roll-forming, the precision of our engineering team, and the diligence of the quality control department, Roller Die can consistently deliver excellent products to your construction site exactly when you need them. This will help you stay ahead of schedule and under budget!

Roller Die

Roller Die has facilities across the United States and Mexico to help reduce your shipping costs and we have an array of machines at each location to satisfy your roll forming needs.

Request a quote today at (502) 804-5571.