While Roller Die + Forming mainly talks about running standard carbon steel through our roll form process. We can actually run a number of different materials for our customers. It’s important for our engineering team to know exactly what material we are rolling. Different materials have different strengths and so are easier or harder to bend and maintain their shape differently.

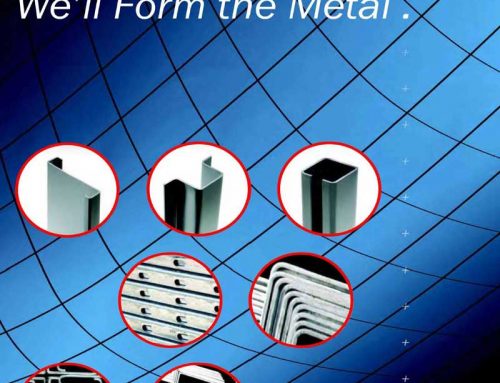

In addition to carbon steel, we typically run stainless steel and aluminum. We can also run brass, copper, and high-strength alloys. Our standard tooling library shows the different shapes we can roll these metals into. Our engineering staff can help create a custom shape specific to your needs. While roll forming is a major part of what we offer, we can also punch holes, stamp, and cut your parts, as well as weld and powder coat.

Our roll form lines can be set up to run 5,000 or more feet of the exact shape you need. From a simple hat shaped stainless steel to an S-shaped piece of aluminum. We’ve worked with many different industries, from making step treads for the automotive industry to racks for solar and material handling and in each case. We bring our understanding of the roll form process to the customer’s desired part to create the best product possible.

To learn more about the different types of materials Roller Die works with, contact our sales staff today or browse our standard tooling library to learn more about our standard shapes.